Preventing Potholes Using Asphalt Crack Filler

Asphalt Crack Fillers and Their Downsides

When it comes to asphalt crack fillers there are a variety of options available, all offering effective solutions for repairing asphalt surfaces and preventing further damage to the area. Not all asphalt crack fillers are created equally and it is essential to consider the limitations and possible downsides when choosing the most suitable filler for specific applications. Let’s take a look at the various options and their characteristics.

Hot pour crack sealants are durable, flexible and water tight, and are effective for sealing small cracks. However, larger, more extensive pavement damage may require different repair methods, such as patching or resurfacing.

Cold pour asphalt crack fillers are convenient, user-friendly, flexible and versatile. They are the perfect temporary solution for minor repairs but may not be as durable or long-lasting as hot pour asphalt crack fillers and should not be used on comprehensive repairs requiring a more permanent solution.

Asphalt Emulsions are a versatile alternative to traditional hot mix asphalt because they can be applied at lower temperatures, which can be more energy-efficient and environmentally friendly. As with cold pour fillers, asphalt emulsions don’t offer the same level of durability or permanence as hot fillers because of their lower temperature.

Modified asphalt crack fillers are specialized products made of materials that are formulated with additives that enhance the properties of traditional asphalt, improving its performance and durability in specific applications. The modifications in these fillers can include various types of polymers, fibers, and other additives that impart desirable characteristics to the asphalt, such as increased elasticity, flexibility, strength, adhesion, and resistance to cracking. While modified asphalt fillers offer many benefits for pavement repair there are many downsides that must also be considered. These types of fillers are more expensive than traditional asphalt fillers and require additional training and experience for effective application. Some modified asphalt fillers contain additives or modifiers that might raise environmental concerns and may also be less readily available than standard asphalt materials. In this article we will dive into the comprehensive nature of RockAsphalt and the permanent solutions it brings to the table.

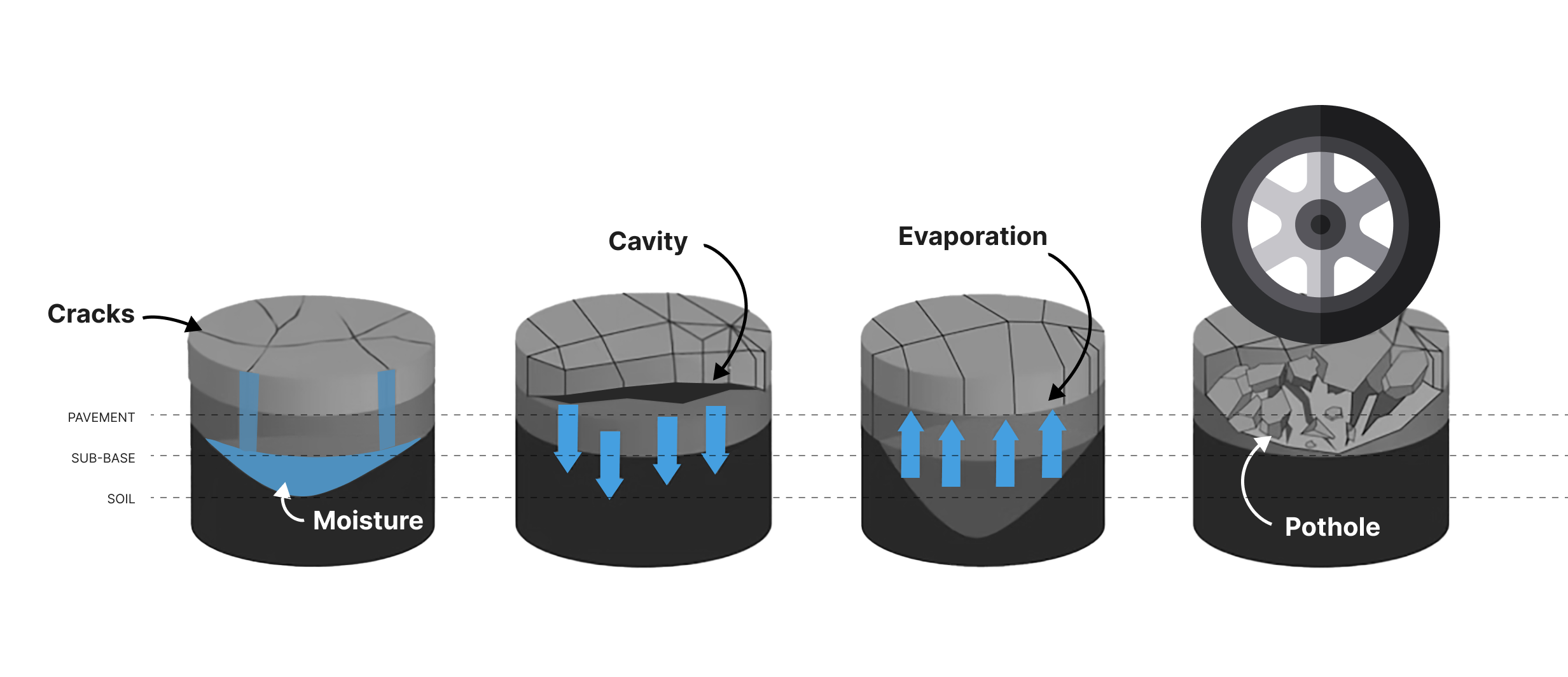

Why asphalt cracks are dangerous

Asphalt cracks may appear innocuous at first glance, but their consequences can be far-reaching and damaging. These seemingly small openings in the pavement can have a domino effect on the overall health and safety of asphalt surfaces and left untreated, cracks provide a gateway for moisture, oil, and debris to infiltrate the pavement structure. This infiltration can lead to a range of issues, starting with the erosion of the sub-base. As water seeps into the cracks and freezes during colder temperatures, it expands, causing the cracks to widen further and compromising the stability of the pavement layers.

The initial investment in crack repair may seem minor compared to the potential expenses associated with extensive pavement deterioration. Research conducted by the Federal Highway Administration (FHWA) and various state departments of transportation has highlighted the economic advantages of proactive crack repair strategies.

A study conducted by the FHWA estimates that every dollar spent on preventive maintenance, including crack sealing and filling, can save up to six dollars in future rehabilitation and repair costs, further emphasizing the immense cost-effectiveness of addressing cracks before they worsen.

Calculations based on lifecycle cost analysis further illustrate the benefits of timely crack repair. A study conducted by the Minnesota Department of Transportation found that the cost of sealing a crack is approximately 1/100th the cost of replacing an entire pavement segment due to failure. Similarly, a study published in the “Journal of Transportation Engineering” estimated that the cost of crack sealing is around $0.50 per square yard, while the cost of an overlay or reconstruction can range from $10 to $30 per square yard. These figures highlight the stark contrast between the expense of routine crack repair and the financial burden of major rehabilitation or reconstruction projects.

An Asphalt Crack Filler That Tackles What The Others Are Lacking

RockAsphalt has made application even easier with a convenient and clean Totes delivery system. Tote bags come in perfectly manageable amounts, prevent waste, and keep your yards clean and free of messy piles. Totes are a complete solution to filling cracks, potholes, and even large scale repairs without the need for any other kind of mix, hot or cold. RockAsphalt Totes can be ordered online through a simple system and delivered either directly to your job site or yard for added convenience.